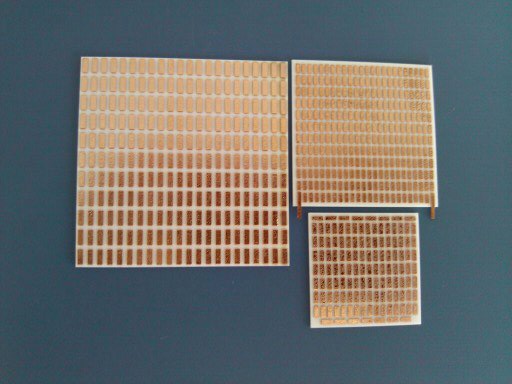

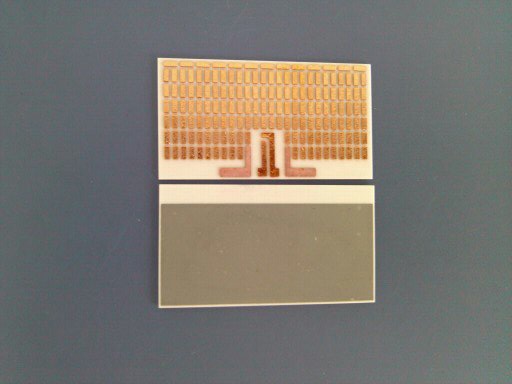

Direct Bonding Copper Ceramics substrate:

DBC is a new high performance substrate materials that according to customer requirements of the circuit diagram directly bond copper (99.99%) and alumina ceramic substrate together , and the materials meet the ROHS requirements.

Characteristics of DBC:

DBC has excellent electrical insulation (anti voltage of 3KV ~ 14kV) and thermal conductivity, high temperature resistance, moisture resistance, corrosion resistance, dielectric performance and stability, good heat dissipation, (heat conduction coefficient 26 ~ 180w/m.K). Excellent thermal cycling performance, high reliability, Mechanical stress, and has high strength binding.

Application of DBC:

As a new and high capability substrate, DBC substrates have been used widely in electric power and electronic industry. The high thermal conductivity of Al2O3 combined with the high thermal capability of thick high purity copper make DBC the most popular material choice for power chip on board assemblies.

The Physical properties of Direct Bonding Copper Ceramics substrate:

| Items | Capability |

| Colour | White with pale gray |

| Density | ≥3.70 g/cm3 |

| breakdown strength | ≥20KV/Mm2 |

| tensile strength | Lead pull test ≥2Kg/mm2, copper metal layer should be without shedding |

| solderability | Copper metal layer dip tin (5s)area of more than 95% 245℃ |

| Resistance to soldering heat resistance | Copper metal layer by more than 5 times the Baptist tin (5s)at 260℃ without shedding |

Regular products specification sheet:

We can according to customer's requirements, customized for various sizes and specifications, with holes and other models of DBC.

| The size of Ceramic | The size of Copper |

| 15X15X0.76 | 3X1.2X0.3/3X1.2X0.4 |

| 15X15X0.76 | 3X1.2X0.3/3X1.2X0.4 |

| 20X20X0.76 | 3.1X1.2X0.4 |

| 20X20X0.76 | 3.1X1.2X0.4 |

| 30X34X0.76 | 3X1.2X0.3/3X1.2X0.4 |

| 30X30X0.76 | 3X1.2X0.3/3X1.2X0.4 |

| 30X30X0.76 | 3X1.2X0.3/3X1.2X0.4 |

| 40X40X0.76 | 4X1.6X0.3/4X1.6X0.4 |

| 40X40X0.76 | 4X1.6X0.3/4X1.6X0.4 |

| 40X40X0.89 | 4X1.6X0.3/4X1.6X0.4 |

| 40X40X0.89 | 4X1.6X0.3/4X1.6X0.4 |

| 40X40X1.0 | 4X1.6X0.3/4X1.6X0.4 |

| 40X40X1.0 | 4X1.6X0.3/4X1.6X0.4 |

| 40X40X0.76 | 3.51X1.38X0.3/3.51X1.38X0.4 |

| 40X40X0.76 | 3.51X1.38X0.3/3.51X1.38X0.4 |

| 40X40X0.89 | 3.51X1.38X0.3/3.51X1.38X0.4 |

| 40X40X0.89 | 3.51X1.38X0.3/3.51X1.38X0.4 |

| 40X44X0.76 | 1.4X3.3X0.4/1.45X3.4X0.4 |

| 40X40X0.76 | 1.4X3.3X0.4/1.45X3.4X0.4 |

| 40X40X0.76 | 1.4X3.3X0.4/1.45X3.4X0.4 |

| 40X44X0.76 | 1.15X2.9X0.3/According to customer drawings |

| 40X40X0.76 | 1.15X2.9X0.4/According to customer drawings |

| 40X40X0.89 | 1.15X2.74X0.3/According to customer drawings |

| 40X40X0.89 | 1.15X2.74X0.3/According to customer drawings |

| 50X50X0.76 | According to customer drawings |

| 50X50X0.89 | According to customer drawings |

| 55X55X0.89 | According to customer drawings |

| 62X62X0.89 | According to customer drawings |

This page:http://www.suntech-ceramic.com/en/b4.aspx

Reproduced please indicate the source